Condensate Drains

The condensate that forms in compressed air systems has to be removed to protect tools, equipment and of course finished product. There are many ways to remove it and each choice has its benefits and its pitfalls.

Contact us for information about Condensate Drains...

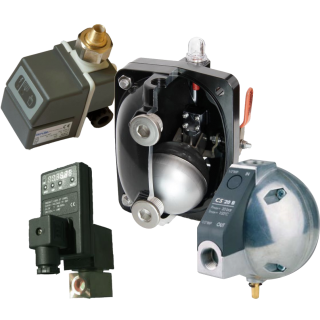

Electronic zero-loss drains.

Typically this type of drain is installed at a lower level than the point being drained, so that condensate collects gradually. At a pre-set level, usually determined by an electronic capacitive sensor, the solenoid operated valve is opened briefly to discharge condensate and closing before air can escape.

This type of drain can save sufficient energy to pay for itself in a few months, but the installation instructions in the manual should be followed to the letter to ensure reliable performance.

Electro-mechanical zero-loss drains.

Very similar to the electronic version, these drains use a magnetic float to sense condensate level and trigger the solenoid valve to open.

Ideal for low volume installations and especially filter housings and water separators. Used in this sort of application, installation is easy.

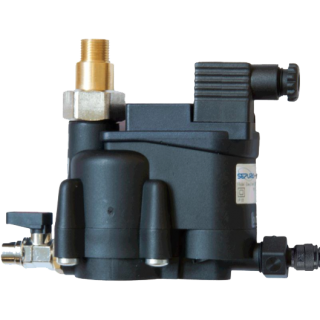

Hybrid automatic drains.

This type of technology is not as widely used as some, but in reality it has much to recommend it. Based around a timed solenoid drain with a fixed frequency and opening time, the hybrid also has a sensor that looks for water in its inlet port.

If there is no water it closes within a few milliseconds, so air loss is minimal. Installation is very flexible; as it opens on a timed sequence the ‘air lock’ that can occur in a ‘lazily’ installed zero-loss drain can’t happen. The down side is the loss of a small amount of compressed air.

Timer controlled solenoid valves.

These are available in various sizes and functional variations, but in principal they operate on a fixed time sequence that is adjustable on installation. These drains are highly reliable and uncomplicated to install. However, they do waste compressed air.

Because the volume of condensate varies considerably from hour to hour and day to day it is impossible to set the sequence to avoid waste.

Mechanical float operated drains.

A simple technology, these drains could be described as mechanical zero-loss drains. Like their electronic counterparts, they collect condensate as it drains in from the system, so installation has to follow the recommendations in the manual. The difference is that the sensor and the valve that controls condensate flow are both mechanically operated by the float.

This is generally considered to be less positive than solenoid operation and therefore less reliable. However, the fact that no power is required is often a positive thing on large distributed sites.

Sepura

Unit 25 Maybrook Ind Est. Maybrook Road, Walsall, West Midlands,WS8 7DG

-

t: +44 (0)1543 379212

-

e: moc.seigolonhcet-arupes@selas